We love sequins, if you search sequin on ASOS over 1,800 products are available – but the traditional sequin is an environmental disaster. They are traditionally stamped out of a sheet which leaves around 30% plastic waste. They are also most commonly PVC which is a petroleum based plastic (i.e finite resources). PVC contains toxic and carcinogenic chemicals which pose a health risk to the environment and humans. The optical iridescent effects are synthetically achieved through hazardous chemicals. Then the sequined garment is typically worn 3 times before the owner discards it. Sequin garments are by definition made up of various different materials and therefore costly and difficult (if not impossible) to recycle. The PVC sequins often end up in the ocean where fish mistake them for food. Sequins, unfortunately share many of the same characteristics as micro plastics. So it’s a pretty bleak picture for something so shiny.

Let’s welcome the plant based Bio Iridescent Sequin, pioneered by Elissa Brunato, fashion designer and material innovator. Brunato realised that the fashion industry lacks sustainable material options particularly for embroidery and embellishment. Her Bio Iridescent Sequin, developed with scientists in Sweden, is a solution for sustainable sequins and shows potential for further lab made environmentally friendly materials and embellishments. The magical part is that the colourful iridescent shimmer is a result of the materials innate micro structure, meaning there are no pigments or synthetic chemical colour fixatives added. The sequins sparkle naturally just like beetle wings or peacock feathers.

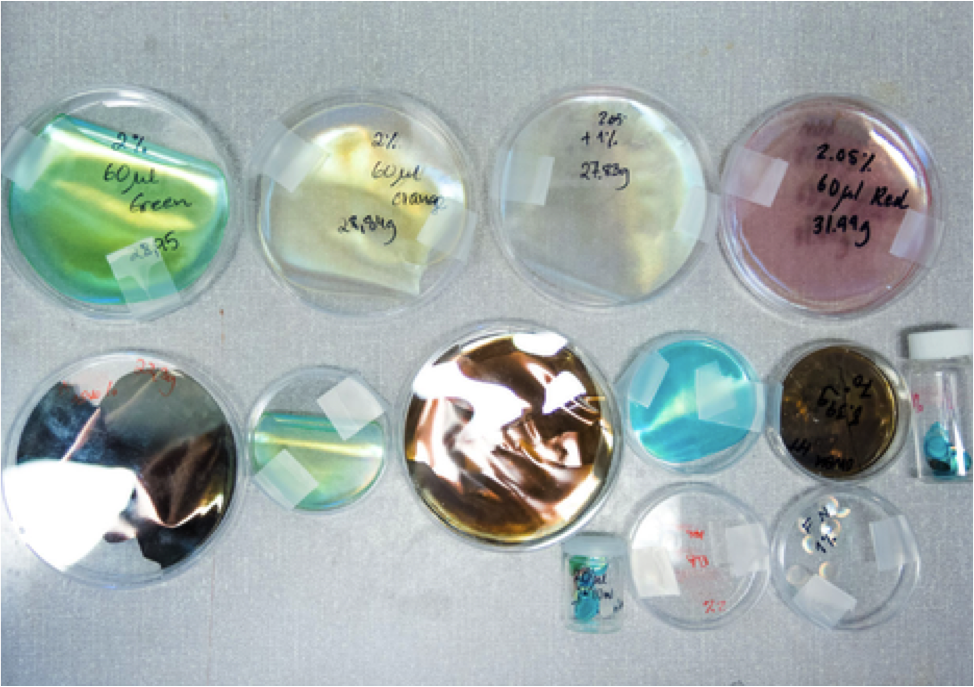

The sequins are made in the lab using cellulose from trees. Cellulose is, according to quora: “…a very important polysaccharide because it is the most abundant organic compound on earth. Cellulose is a major component of tough cell walls that surround plant cells, and is what makes plant stems, leaves, and branches so strong”. So the crystalline form of cellulose is extracted from trees which is then grown into the sequin. The process takes 24 hours and is chemical free. The sequins are grown in moulds meaning literally zero waste. Brunato states the material is light and as strong as plastic but also compostable at the end of life!

Pictures courtesy of: http://www.elissabrunato.com/future_sequin.html